From Kona Coffee Farm to Cup of Coffee: Our Quality-Oriented and Sustainable Production Cycle

Have you ever wondered how Kona coffee is made? We frequently discuss the roast profile, growing locations, tasting notes, and so on, but we rarely get a true glimpse into each step of the growing process. Our 100% Kona coffee is grown exclusively on our farm. As an Estate farm, we carefully manage all stages of the production cycle to ensure that we comply with the highest quality standards for specialty coffee, while employing sustainably and eco-friendly practices: from seedling, growing, harvesting, processing, drying, milling, grading/sorting, and finally roasting. Follow along as we trace the origins of the World's most famous coffee, from seedling to roasting to a steaming mug.

What is Kona coffee?

Kona Coffee is coffee grown only within the Kona District, located on the Big Island of Hawaii's west side, on the western slopes of the Hualalai volcano (Central and North Kona) and the Mauna Loa volcano (South Kona). The volcanic ecosystem provides a rich volcanic soil with all of the nutrients necessary to grow the coffee beans, as well as a very unique microclimate that aids the growth, providing a consistent morning sun along with the afternoon rain throughout the year, making this location ideal for growing high quality coffee.

How Kona Coffee Is Made: Seedling to Roasting

The morning sun evaporates ocean water, and trade winds carry the newly formed clouds to the Hualalai and Mauna Loa Volcanoes' slopes. These clouds eventually grow large enough to condense into afternoon moisture, creating the ideal combination of sun and rain for coffee cultivation. This incredible microclimate also allows most Kona Coffee farmers to forego any formal irrigation of their trees. The consistent afternoon rain is usually enough throughout the year to keep the trees watered and healthy.

Growing Kona coffee seeds

Kona Coffee begins as a green coffee seed. It takes about 60 to 75 days for the seeds to germinate, then about one month for the seedlings to be ready to be transferred to pots, where they continue growing for about eight months until they are ready to be planted in the ground.

Traditionally, Kona Typica has been the coffee variety grown and processed to produce the world-famous Kona Coffee. Kona Typica is well known for its incredibly smooth, non-bitter, and floral flavor profile; but also other coffee varieties with excellent flavor notes, like Bourbon, Maragogype, Gesha, Pacamara, Catuai, Moka, Caturra, are being grown in Kona and other coffee growing regions in Hawaii.

Blossom to Red Cherry Growth Cycle

It takes three to four years after the new seedlings are planted before they produce a significant yield of coffee. The growing cycle begins with sweet, pungent coffee blossoms known as "Kona Snow" in Hawaii. Between February and March, the Kona coffee trees start blooming. The trees are covered with small white flowers. These blossoms eventually develop into a green coffee cherry, which takes about seven months to mature and be ready to be harvested. The term "coffee cherry" refers to how similar the ripe coffee husk (cascara) looks to the popular red cherry fruit.

Kona coffee ripens in the late summer-fall to early winter. This ripening window, however, can vary greatly depending on elevation. The Hualalai and Mauna Loa volcanoes' slopes are relatively steep, with large temperature variations depending on how low or high the farm is located. When compared to lower-elevation farms, higher-elevation farms have a lower average annual temperature. The lower daily temperature causes the coffee cherries to ripen later in the season, resulting in a much longer harvest season.

Each tree is hand-picked several times year-round, mainly between August and January, producing an average of 15 pounds of cherry. This amount is equivalent to about 2 pounds of roasted coffee (it takes about 7.5 pounds of cherry to get 1 pound of Roasted coffee).

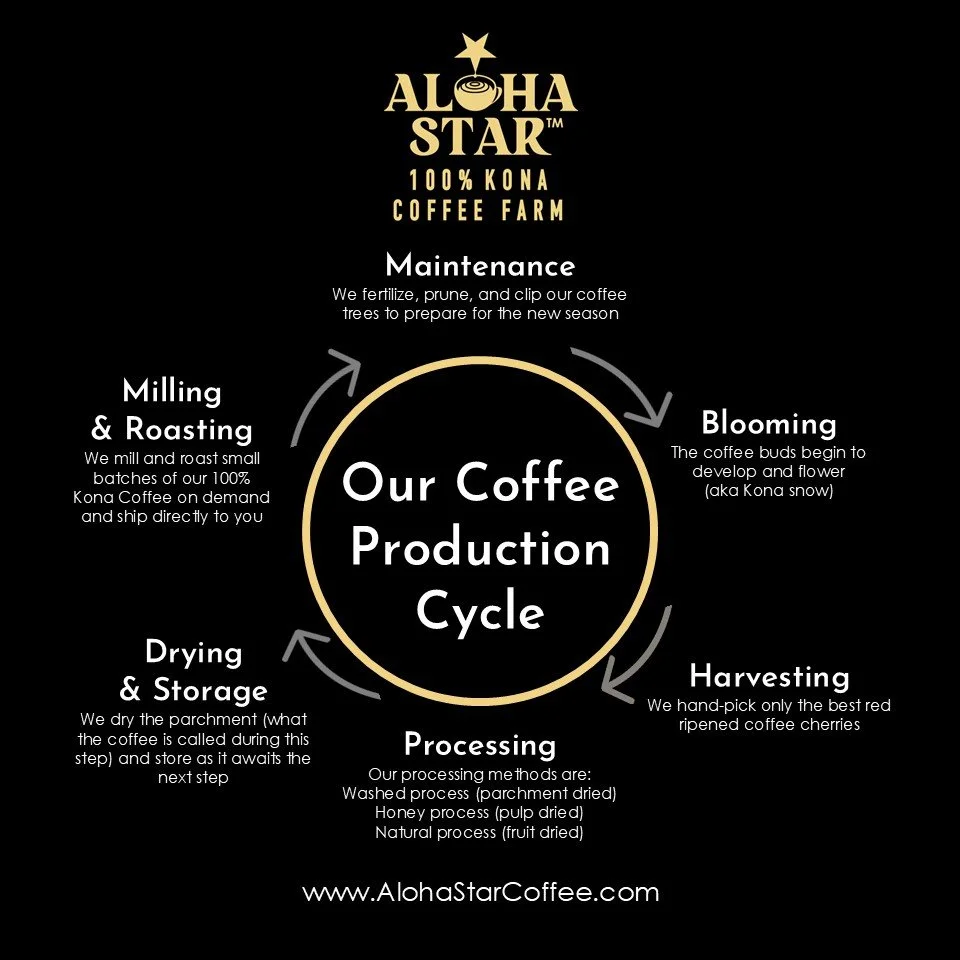

The Kona Coffee Production Cycle

As an Estate farm, we continuously take care of our coffee trees and our farm. We carefully manage every step of the production process, from beginning to end. We are on the field picking the coffee cherries alongside with our pickers. We personally process our beans, set the parchment to dry under the sun. We also manage the milling (removal the parchment), grading/sorting of the green beans, roasting, packaging, and shipping.

Here is brief description of each stage of the coffee production cycle:

Maintenance of the trees: Fertilizing, pruning and clipping.

Previous to the trees blooming, the pruning of the trees is done usually during the month of January. Pruning is the act of removing the oldest branches from the trees, to allow new branches to grow and produce coffee. With time, the amount of coffee produced by a branch decreases. The pruning keeps better rates of coffee production by tree, resulting in a bigger crop with better quality beans. Usually, each branch is cut every three years, depending on how healthy and productive it is every year. The clipping is done usually during spring and first months of the Summer. The goal of the clipping is to keep just the sprouts that will be allowed to become large branches for producing coffee.

The fertilization is done several times a year, usually before blooming, during the development of the cherries, and between pickings (not all the beans mature and ripen at the same time).

Hand Picked Harvest

Our Kona Coffee is hand-picked, the trees are harvested multiple times throughout the several-month harvest season because the coffee cherries do not ripen at the same time. The coffee picker will only select the bright red cherries, leaving the rest to ripen for the next pass. Although hand-picking is time-consuming (and thus expensive), it ensures that only the best cherries are harvested. Furthermore, by allowing unripen fruit to remain on the tree until it is ready, the yields from each tree during a season are maximized.

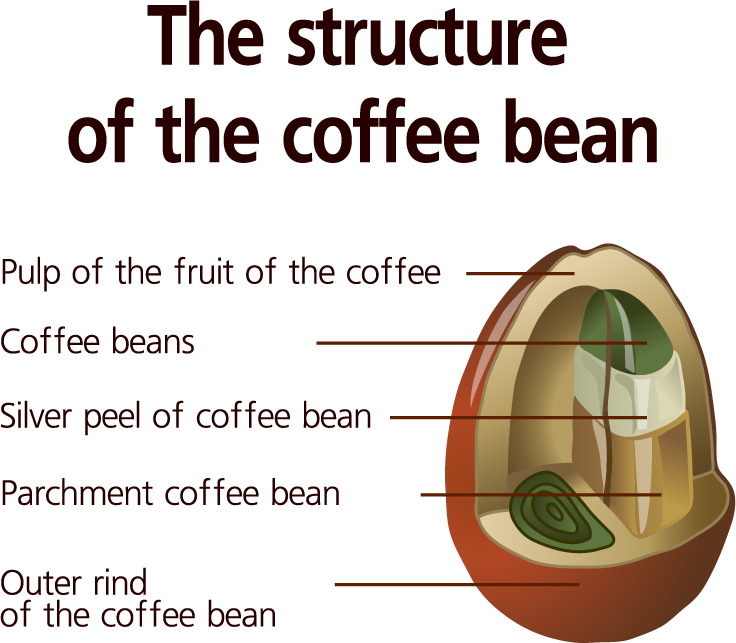

Structure of a Coffee Cherry

Each coffee fruit (cherry) is formed by several layers. The outer skin (pulp) or exocarp; the mucilage or mesocarp, a silky, sticky layer that’s responsible for much of the coffee’s sweetness; a papery layer or endocarp called parchment; and the silver skin, a membrane which covers the two seeds. Two coffee beans are typically found in a coffee cherry. In the case of the Peaberry, there is only one bean formed within the cherry. A "peaberry" is a rare exception (considered a genetic defect) in which the cherry only contains one smaller, round coffee bean. This happens in about 5% of the coffee harvested each year.

Kona Coffee Processing Stages

Coffee processing is generally defined as the removal of coffee cherry’s layers of fruit. However, there are several processing methods, each one involving different stages and producing different results on the coffee flavor notes.

Our current processing methods are:

Washed (Parchment-Dried).

Honey (Pulp-Dried).

Natural (Fruit-Dried).

Although the washed coffee process is the most popular for Kona coffee processing, in recent years, the Honey (pulp-dried) and the Natural (fruit-dried) methods, which are widely used in other countries and coffee-producing regions, we are part of a small group of Kona coffee farmers who are employing these two additional processing methods (Honey and Natural ) to fulfill the increased demand from coffee lovers for specialty coffee (“third wave coffee”), who are looking to experience flavorful and “bright” tasting notes of the final cup.

Rising and Floating

Once the coffee cherries have been harvested, they are processed within 24 hours. The first step is to rinse and float the coffee cherries. The coffee cherries are placed in large tanks with water to get rinsed and floated, to allow all the underripe, overripe, or dried beans to "float", and be discarded, as well as removing leaves, any branches, or any other debris, before the pulping stage begins (for Washed and Honey processing) or before setting the coffee cherries to dry without pulping (for the Natural process). “Floaters' is the name given to the immature, dry, or over-ripe coffee cherries that stay in surface (floating) and do not go to be bottom of the tank (good quality beans will stay in the bottom). After the floaters and debris are removed, the coffee cherry processing begins. The steps involved in the processing will vary, depending on the method employed.

2. Pulping (Removal of the red skin or cascara)

For Honey and Washed methods only, with Natural process, the cherries are not pulped: After being "floated", the cherries run through a mechanic pulper, where the red skin (cascara) is removed (pulped). On this step, the beans are separated from the pulp. We employ the removed skin as weed control, spreading it all over the ground, where it will decompose and eventually converts into soil.

3. Drying

For all processing methods, our coffee beans are transported to the drying shed to let them dry just using sunlight. For all three processing methods, we employ elevated drying beds, instead of the traditional hoshidana, for a more effective air circulation. To ensure even drying of the coffee parchment (Washed or Honey process) or the whole fruit (Natural process) the Kona Coffee beans must be "raked" several times per day during the drying stage. The coffee beans are dried until they reach the optimal moisture levels (between 10% and 12%) to protect the coffee bean quality and prevent mold.

Depending on the processing method employed, and the weather conditions, the drying time varies:

For Washed process (parchment dried): 4 to 7 days. The beans are now called “parchment", because this is the layer that is covering the beans at this point.

For Honey process (pulp dried): 7 to 10 days. The “parchment” layer is covered by the mucilage (remaining pulp not removed during the pulping). This process is called Honey because it has a sticky, honey-like texture and color when the beans are touched.

For Natural process (fruit dried): 15 to 21 days. This process has the longest drying time, because all the layers of the coffee beans need to get dried (skin, pulp, parchment).

Once the beans are dried, they are stored in sealed, food-grade plastic bags, to protect them from moisture, light and to prevent the formation of mold.

4. Storage of the dried beans

Coffee beans can be stored in this dried form, for months before roasting with little to no impact on quality, if properly protected from the elements.

5. Dry milling, HDOA grading, and optical sorting before roasting

Before roasting the coffee beans, the parchment and silver layers are mechanically removed to expose the “green” coffee beans (because of their color). This process is known as “dry milling”. After all layers are removed, with the help of a gravity table, the green coffee beans are graded and sorted by size and density with the objective to remove smaller and defective beans that are not compliant with the Hawaii Department of Agriculture (HDOA ) grading standards stablished for 100% Kona Coffee.

Additionally, we employ a green coffee optical sorter, which removes additional defects not removed during the initial grading and sorting done with the gravity and density table. This step allows to comply with the Specialty Coffee Association quality standards for green coffee beans (unroasted coffee beans). After the completion of this stage, the “green” coffee beans are ready for roasting, or to be stored for later roasting. To ensure the maximum freshness, we only mill our beans when we need to fulfill and order of either green or roasted coffee.

6. Roasting

Our specialty-grade green Kona coffee beans are roasted “on-demand”, usually once a week, depending on the orders volume. We employ and “old fashion” manually operated roaster with 20 lbs. capacity drum, that allow us to roast small, customized batches. The heat from the flame is transferred through the metal housing via conduction as the drum rotates. It allows for very precise temperature control throughout the roasting process.

We have three roast levels for you to choose:

Medium, similar to a "City+ / American", roasted to a mid first crack.

Medium-Dark, “Full-City”, roasted before the second crack.

Dark. similar to a “Vienna” roast, is roasted to mid-second crack, is the lightest of the dark roasts.

Plus, our top seller, Constellation 100% Kona, which is a special combination of our farm’s roasts, resulting a “constellation” of flavor notes, that makes it highly demanded.

As an Estate farm, we only sell what we grow, and we carefully manage each stage of our Kona coffee production in an ongoing effort to provide the best coffee possible. We hope that the next time you enjoy a cup of our 100% Kona Coffee, you will have a new appreciation for how much work we put to produce that amazing cup.